Top/Bottom Wedge PaperInsertion Machine

- Home

- Top/Bottom Wedge PaperInsertion Machine

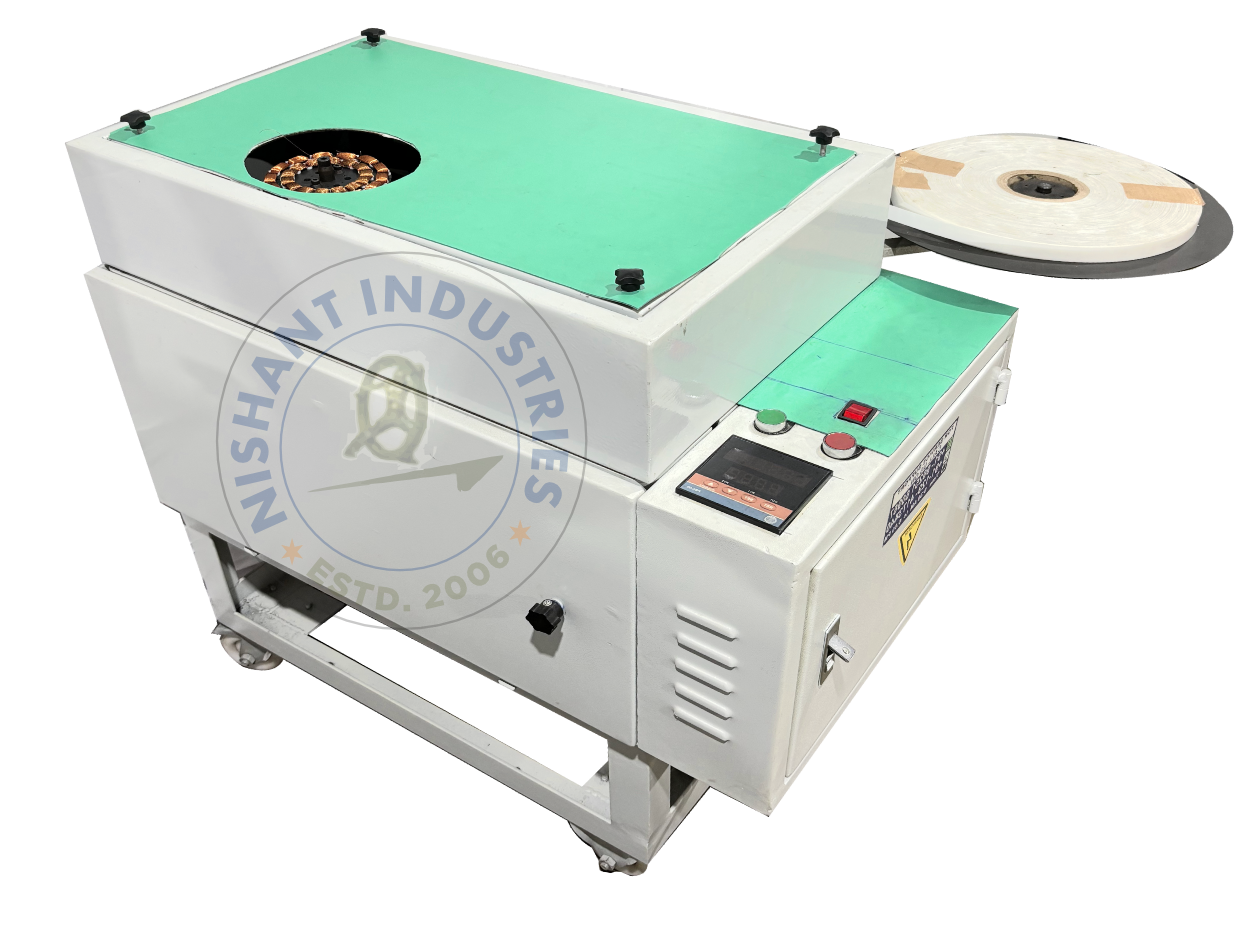

Top/Bottom Wedge Paper Insertion Machine

This Stator Insulation Paper Inserting Machine is designed for bottom paper

insertion, inserting insulation paper into the stator slots from the bottom side

with high accuracy and consistent performance.

Pre-Production Sample

- Technical SPECIFICATIONS

| Parameter | Specification |

|---|---|

| Stator Stack Length | 20~160mm |

| Stator OD | Max 190mm |

| Stator ID | 50~120mm |

| Folding Height / Width | 2~4mm / 4~7mm |

| Paper Thickness | 0.188~0.35mm |

| Efficiency | 0.8 s/slot |

| Power | 380V / 50-60Hz / 0.75KW |

| Machine Weight | 250 Kg |

| Machine Dimension | (L)1200 × (W)650 × (H)1200 mm |

- CONTROLLERS FEATURES

Introduction

This Stator Insulation Paper Inserting Machine is designed for bottom paper

insertion, inserting insulation paper into the stator slots from the bottom side

with high accuracy and consistent performance.

Machine Functions & Features

Provides clean, burr-free, and damage-free cutting of insulation paper. Ensures

the stator does not deform and prevents upward movement of stator

laminations during bottom insertion. Fully interchangeable tooling set with a

quick changeover time of approximately 30 minutes. Automatically stops the

machine in case of paper jams, ensuring safety and preventing defects.

Equipped with a text display panel for easy setting, adjustment, and

monitoring of parameters for different stator models. High quality assurance:

Primary qualification rate 99%After rework qualification rate

99.9%Production capacity: 1 second per slot (excluding loading and

unloading).

Paper specifications: Paper width = stator stack length + 14 mm Folded edge

dimension can be customized based on customer requirementsOperator must

stand during operation; machine uses a single-hand control button for safe

operation. Suitable for Polyester Film insulation paper roll material with 0.25

mm thickness and fixed width defined by the customer.

Application

This Insulation Paper Inserting Machine is ideal for small and medium-sized

three-phase motors, gasoline generators, and similar stator assembly

applications.