Auto Coil winder for Submersible Pump

- Home

- Auto Coil winder for Submersible Pump

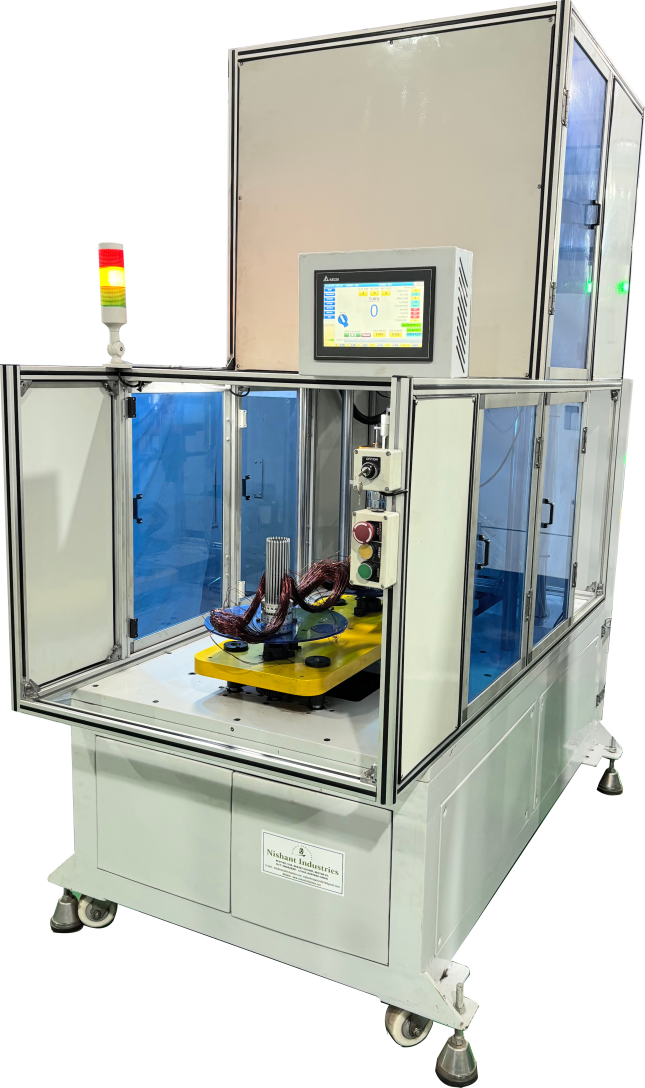

Auto Coil winder for Submersible Pump

The Automatic Submersible Pump Motor Stator Coil Winding and Insertion

Machine is designed with a four-station working concept, featuring three

winding stations and one coil insertion station. It enables fully automated coil

winding and precise stator slot insertion for submersible and deep-well pump

motors. With mature technology, high production efficiency, and low labor

demand, the machine supports winding for 2-pole, 4-pole, and 6-pole threephase submersible pump stators.

Pre-Production Sample

- Technical SPECIFICATIONS

| Parameter | Specification |

|---|---|

| Appropriate Wire | 0.2–1.2mm |

| Stack Height | 30–80mm |

| Stator OD | 150mm |

| Stator ID | 40–80mm |

| Winding Stations | 3 |

| Coil Inserting Stations | 1 |

| Height of Coil | 3 |

| Winding Mode | Chained / Same Core |

| Voltage | 380V 50/60Hz |

| Power | 15 KW |

| Dimension | 4050 × 3000 × 2500 mm |

| Weight | 4000 Kg |

- CONTROLLERS FEATURES

Introductions:

The Automatic Submersible Pump Motor Stator Coil Winding and Insertion

Machine is designed with a four-station working concept, featuring three

winding stations and one coil insertion station. It enables fully automated coil

winding and precise stator slot insertion for submersible and deep-well pump

motors. With mature technology, high production efficiency, and low labor

demand, the machine supports winding for 2-pole, 4-pole, and 6-pole threephase submersible pump stators.

Main Features & Functions

Full Servo Control System: Equipped with a complete servo-driven mechanism,

ensuring high precision, smooth operation, and stable coil positioning. DualPower Coil Insertion: The insertion workstation uses a dual-power push system

to achieve high slot-fill rates required for submerged motor windings. Integrated

Winding & Wedge Processing: The machine combines coil winding, wedge

inserting, and shaping functions, eliminating manual transfer errors and ensuring

coil integrity. Four-Station, Three-Head Winding Design: Three stations perform

continuous winding while one station inserts coils, ensuring high efficiency and

minimizing labor dependence. Simultaneous Dual Wire Winding: Capable of

winding two wire sets at once, enhancing coil density consistency and improving

output speed. Automatic Phase Insulation Paper Insertion: Features two paper

insertion units to add phase insulation automatically, reducing manual labor and

eliminating post-processing delays. Automatic Coil Loading to Tooling: Coils are

wound directly into tooling during production to prevent enamel damage, wire

crossing, and tangling. Programmable Parameters: Winding data, insertion

height, wedge pushing, and product stack thickness can be programmed

through a touch screen HMI for easy adjustments and product changeover.

Application

This Submersible Pump Motor Coil Winding & Insertion Machine is suitable for

manufacturing stators used in: Submersible Pump Motors, Deep-Well & Borewell

Pump Motors,Sewage & Drainage Pump Motors, Industrial & Agricultural Water

Pump Motors,